‘Ere did you know that the name of the most famous sword in British ‘istory’s actually French?

Excalibur, the name of the legendary sword carried by King Arthur, was originally called, by Geoffrey of Monmouth, the first person to write down the story of Arthur in 1136, Caliburnus, and French sources, including Chrétien de Troyes who famously romanticised the story (and alleged it was Gawain who carried it, not Arthur) translated that as Escalibor, and Sir Thomas Malory, the author of Le Morte d’Arthur, the classic English-language chronicle of the Arthurian legend (published by William Caxton, the first person to use a printing press in England), changed that to the Excalibur we know today. Actually, there’s some doubt as to whether Thomas Malory actually existed (the book may’ve been written by someone else) so it could all be made-up bollocks… do you know what? I never learnt anything as interesting as this in history at school, y’know, why didn’t they teach us cool stuff like this?

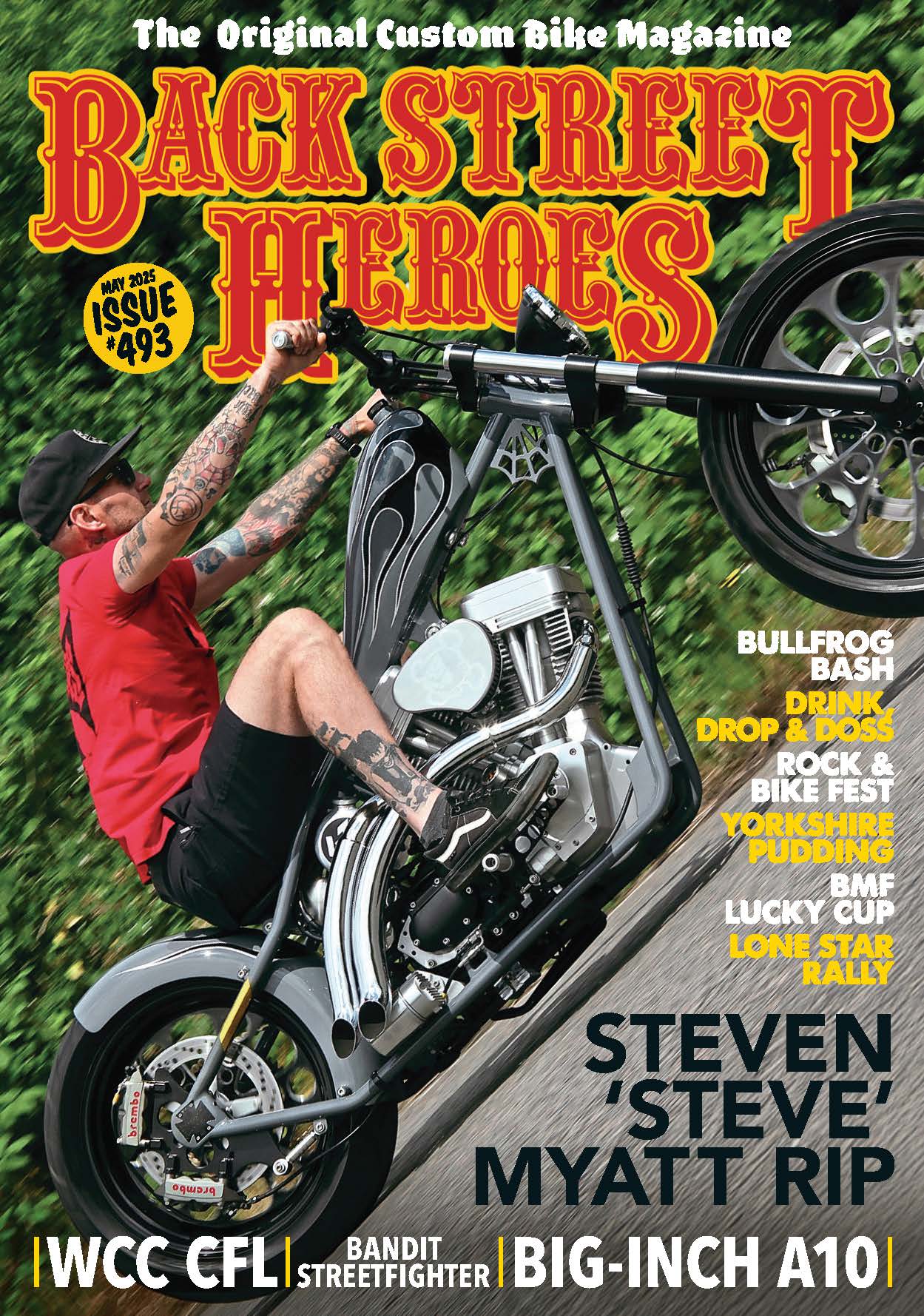

Anyway, Excalibur, no matter its historic importance, is also the name of Dutch from NCC Herts’ well-respected bike-building emporium (well, large shed/workshop) in Shefford, just off the A505, in Herts – Excalibur Engineering. He built this monster FJ 1100 Yam a couple of years back – it’s one of those bikes you keep hearing about before you see it (‘Have you seen Dutch from Herts’ FJ? It’s bloody mad… and massive’), and the first time I actually saw it was on the M1 just outside London on the way to Diamond Day last year when, as I was blatting along at about 90 on the silly-sided Bandit, he came past me like I was going backwards. ‘Bloody hell,’ I thought, ‘that MUST be Dutch’ as this absolutely huge, very, very long, and very, very green behemoth of a bike howled past.

It all started when he picked up an old (well, 1989) FJ 1100 as a donor bike. It was tired, and had a few bits missing, and it sat round his place for a while before he decided what he wanted to do with it – something different, but with suspension (‘40 years of riding rigids will do that to you…’). Back in the ’80s and ’90s, the NCC was famous for building radical bikes (Mick Fish’s twin front end Norton; Hank’s ‘The Fly’; almost anything Twizzle made; Paul Scott’s ‘Road Creature’, etc.), but as the years went by and we all got older, less flexible and (whisper it) more sensible, Club bikes evolved away from radical to capable of doing the mileages Chopper Club guys do and, with the exception of the long Swedish-style bikes made by Cornwall and others, it’s been a while since we saw a radical build.

Of course, Dutch didn’t start out trying to start a resurgence in OTT-bike building – no, he was just doing what felt right. He had some rolled two-inch (diameter) CDS tubing already bent in appropriate curves so the basic idea for the frame was born. He also had a set of Fat Bubba yokes, and a Triumph 955i single-sided back end (with a buggered shock), and fancied a matching three-spoke front hoop, but finding a 19-inch front three-spoke proved nigh on impossible, so he made do with an 18-incher from a Pan-European Honda (one of them big mile-munchers favoured by tourers, long-distance couriers, and gentlemen in blue serge) that he had to adapt to work by removing all the ABS gubbins fitted to it.

With these essential components sourced, he positioned them all in his jig, and set the tubes in place, shortening/shaping where necessary, and TIG-welded it all together. Next job was the forks – a set of conventional telescopic tubes of this length would’ve been prohibitively expensive (and, anyway, why would he buy something he could make himself?), and so he went about creating what you see here in a slightly unorthodox way; the forks had to fit the yokes, so a pair of large-diameter hollow-threaded bushes/spigots were made to fit into the yokes, and the design for the bottom pivot rockers came about by scaling up a Honda PC50 (no, really!) front end, machined out of solid stainless with roller bearings everywhere. The (very!) long 60mm diameter stainless tubes for the front end were originally two feet longer, but even he thought that was a step too far (the bike was just enormous!), and shortened them, deraking the frame a bit to suit.

He hand-formed the tank and side panels from sheet steel; the tank’s underslung with a gap under the top frame tube, and’s split front to back – the front holds 18-plus litres of fuel (really!), giving him plenty of range for long Club runs, while the back section’s for the coils, and features a neat louvred panel underneath to dissipate excess heat. Similar thought’s gone into the oil cooler at the front of the motor – he made it to follow the curve of the frame and, as it had to be finned for air-flow over it, he decided the exhaust downpipes needed to be finned as well to ensure the lines of the bike meld together unobtrusively.

With the dry build done, he pulled the monster FJ down to its constituent pieces and sent the wheels, swingarm and sundry parts off to be powder-coated; the forks, ’bars, cases, etc., to the famed Doug Heath Plating just up the road in nearby Baldock, and set about doing the paint as he saw it in his mind’s eye. He has a paint studio back at home (meaning, sensibly, the workshop doesn’t get covered in over-spray), and here he worked out what he wanted – the multi-layer greens; the fish scales; the flame-like, almost tentacle-like artwork; and the black edging, etc. There’s flake in there, too, and it absolutely sparkles in the sun – lovely! It’s got a couple of scars in it now, sadly, ’cos it’s a bike that gets used, but he’s confident he can repair it invisibly so that’s okay then.

So what’s a gargantuan like this like to ride? Well, as I said, he passed me at speed, and it was tracking straight and true, and while doing the cornering shots for this article he looked completely at home aboard it, too. The howl from the four-into-two exhausts, with single plate baffle, is genuinely aural sex, and it’s bikes like this that make their inevitable electric replacements so unappetising. It rides, he says, and handles very well once over a couple of miles an hour (it’s a little flighty at very low speeds), and it’s fast, and comfy to sit on over long distances, as a Chopper Club bike should be. By the time you read this, he’ll’ve taken it on the NCC Mega-Run to Belgium this year, packed up with gear, and then, as he has plans for a Sidewinder V8 bike (a transverse-mounted V8 engine with the output shaft running perpendicular to the bike’s long axis), it’ll be up for sale – ring him on the number hereabouts if you feel you’re man enough to give it a home!

Spec:

1989 Yamaha FJ 1100 engine (Yamaha XJR 1300 carbs, Powercross cone air-filters, Dynatek coils, one off finned down pipes/twin two-into-one collectors with single plate baffles, one-off curved finned oil cooler, rubber lines), one-off two-inch curved tube frame in CDS by owner, Mapam forwards/rear ‘pegs, laser-cut stainless hangers, one-off stainless gear linkage/modified lever, Honda Pan European front wheel (modified), aftermarket wavy discs, Nissin 6-pot front calipers, one-off 60mm front end (stainless tube forks/stainless rocker arms with roller bearings/Honda CM400 shocks fitted internally/stainless cross- brace/mudguard mount/curved struts), H-D steam (modified), Fat Bubba 5-degree rake yokes (modified), stainless braided lines (running through bars/forks), one-off stainless tiller ‘bars, Kawasaki VN front brake master-cylinder, aftermarket switchgear/GPS mini speedo/billet grips, one-off stainless clock surround, one-off front mudguard/underslung split fuel tank/seat (covered by A&R Pound)/side-panels/stainless undertray/electrics box, Triumph 955i single-sided swingarm/wheel/caliper/master-cylinder, YTS shock, one-off loom, aftermarket headlight/tail-lights/’bar-end LED indicators

Finish:

Candy emerald green over silver metalflake paint with black detailing by owner, powder-coating by Perfect Coatings (01462 819222 or www.perfectcoatings.co.uk), plating/polishing by Doug Heath Polishing & Plating (01462 896680)

Engineering:

Bike built & all engineering by owner at Excalibur Engineering (07745 343085 or Facebook)

Thanks To:

“Will at Wilco Sheet Metal (01462 671885 or www.wilcosheetmetal.com) for laser-cutting; Doug Heath for polishing/plating, & A&R Pound (01462 892704) for seat covering…”