Here’s a design patent from Yamaha that’s going to blow a few minds – a carbon-fibre framed motorcycle that BRUISES when the frame is damaged, even if the bike falls over at a standstill.

It might sound like a thought-pattern straight from the latest sci-fi blockbuster movie, but the truth of the matter is that this plan to shift road-going chassis into the next phase of everyday motorcycle reality IS happening in the Yamaha laboratories right now.

The patent was filed just weeks ago under the title ‘Leaning Vehicle’ making it suitably vague to find in the United States patent office, but now it’s been unearthed by MoreBikes you can see that the details of what this design actually contains are pretty jaw-dropping.

Enjoy everything More Bikes by reading the MoreBikes monthly newspaper. Click here to subscribe, or Read FREE Online.

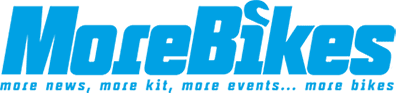

In the extensive 29 page document, Yamaha outlines its plans for a motorcycle (using the current FJR bike in the illustration – could this mean that the bike where this tech is first seen will be a large capacity, fast sport tourer?) that has a carbon-fibre resin main frame with a carbon-fibre resin subframe bolted to it.

Yamaha explains that for a production motorcycle, there are issues with flex in the chassis and that to overcome this so that the motorcycle is sturdy-enough on the move, the chassis has to be stiffened up. The downside to this is that the frame and subframe can suffer from cracks or other damage when the bike goes over on its side, even at a standstill.

Obviously, this is a worry for when this chassis tech turns up on a future production motorcycle, so the solution is four fold – according to this document.

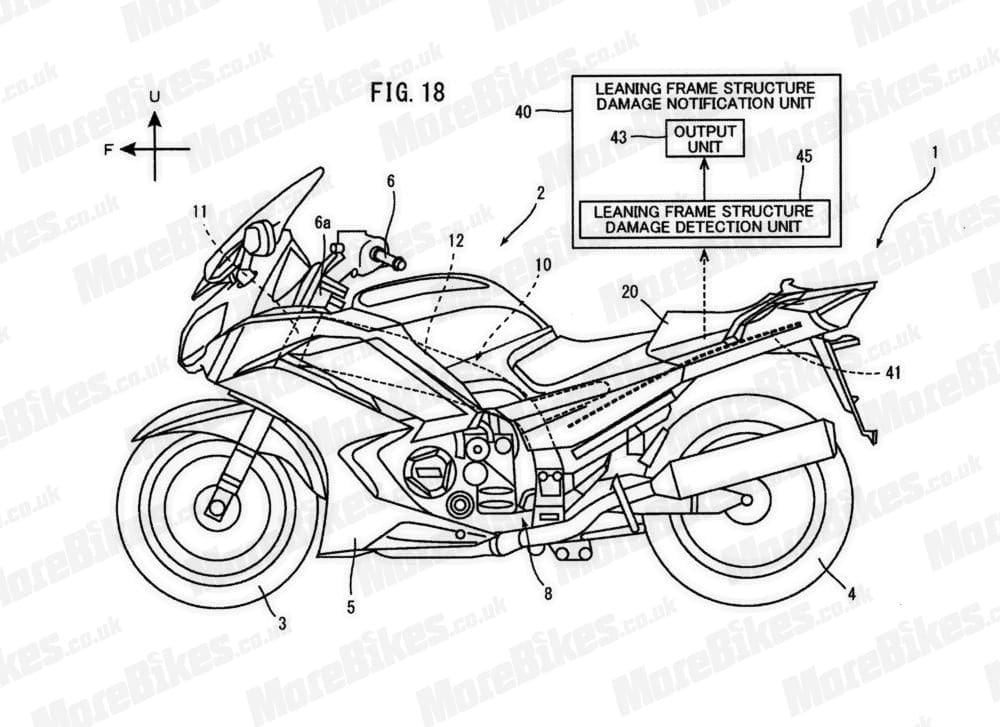

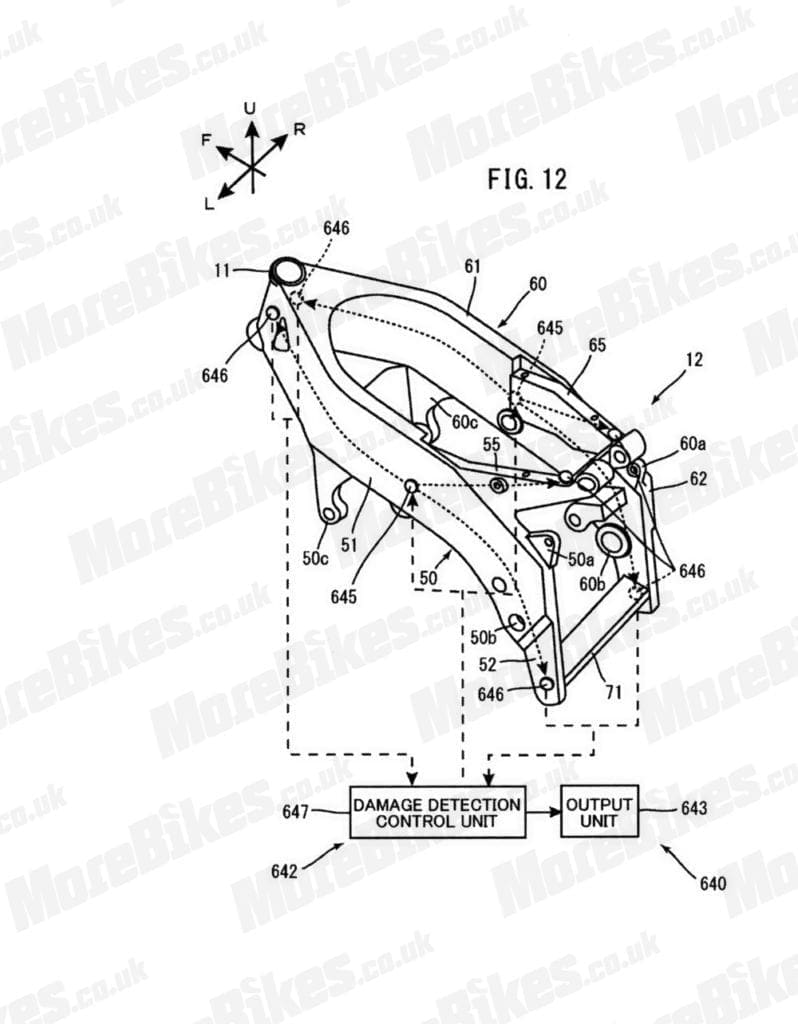

Firstly, the carbon-fibre resin chassis has an electric cable actually put into the structure of the frame during manufacture. The cable has a slightly lower resistance to impact than the carbon-fibre resin material around it. Once the bike falls over, even at a standstill, the cable is damaged and this then sends an alert to a Damage Detection Control Unit (DDCU).

Secondly, the DDCU can notify the rider of damage to the frame (throughout the document Yamaha is concerned about damage, including chassis cracks, appearing on the inside of the frame where it wouldn’t be easily spotted visually without a tear-down of the motorcycle’s major component parts). There are a couple of options for this in the document including swapping out the idea of the electric cable for a fibre-optic version with will also detect chassis differences between the main frame and the subframe.

Thirdly, the actual material that the chassis is made from changes colour with this being triggered by a relay from the optical cable secreted into the carbon-fibre resin construction. Whatever colour the entire chassis is, where it’s damaged then it’s that area specifically that would change colour – effectively this is a bruise on the chassis of the motorcycle.

Finally, an option also discussed in the document is a paint applied to the chassis that emits LIGHT when damaged. The idea being that the entire chassis is coated in the material that, when the outer layer is damaged in even a small way, allows light to penetrate the top layer making damage-identification easy. Yamaha says that this final option is cheaper than any of the others.

In terms of when this sort of tech is likely to make it to the current motorcycle world, it’s very difficult to say. This patent document was filed weeks ago and as far as we know, this is the first time such an idea has been explained in relation to a carbon-fibre resin framed motorcycle set for production.

It could take years before these trick chassis touches actually become common on motorcycles (if they ever make it at all), but for now this is the current state of thinking deep in the future-tech corners of Yamaha.