After the excitement surrounding the track-based H2R, the road-going Kawasaki H2 is here, and we can reveal that it’s capable of an incredible top speed of 209.2mph.

In 1999, Suzuki’s first Hayabusa was clocked on track at 200.1mph, and its gearing pointed to a possible top speed of 200.7mph at the 10,800rpm rev limit. The Kawasaki H2R has a maximum engine speed of 14,000rpm, so calculating a theoretical top-speed based on the gearing ratios from the 210bhp engine tells us that this bike will be faster than a first-generation Hayabusa in the first three gears, about the same in fourth and fifth, then capable of eeking out the extra speed in sixth. Or it would, if – under the long-standing gentleman’s agreement – the ECU didn’t restrict things when the needle hits 186mph. Still, the Bridgstone Battlax RS10 tyres are ‘only’ rated to 186.4mph.

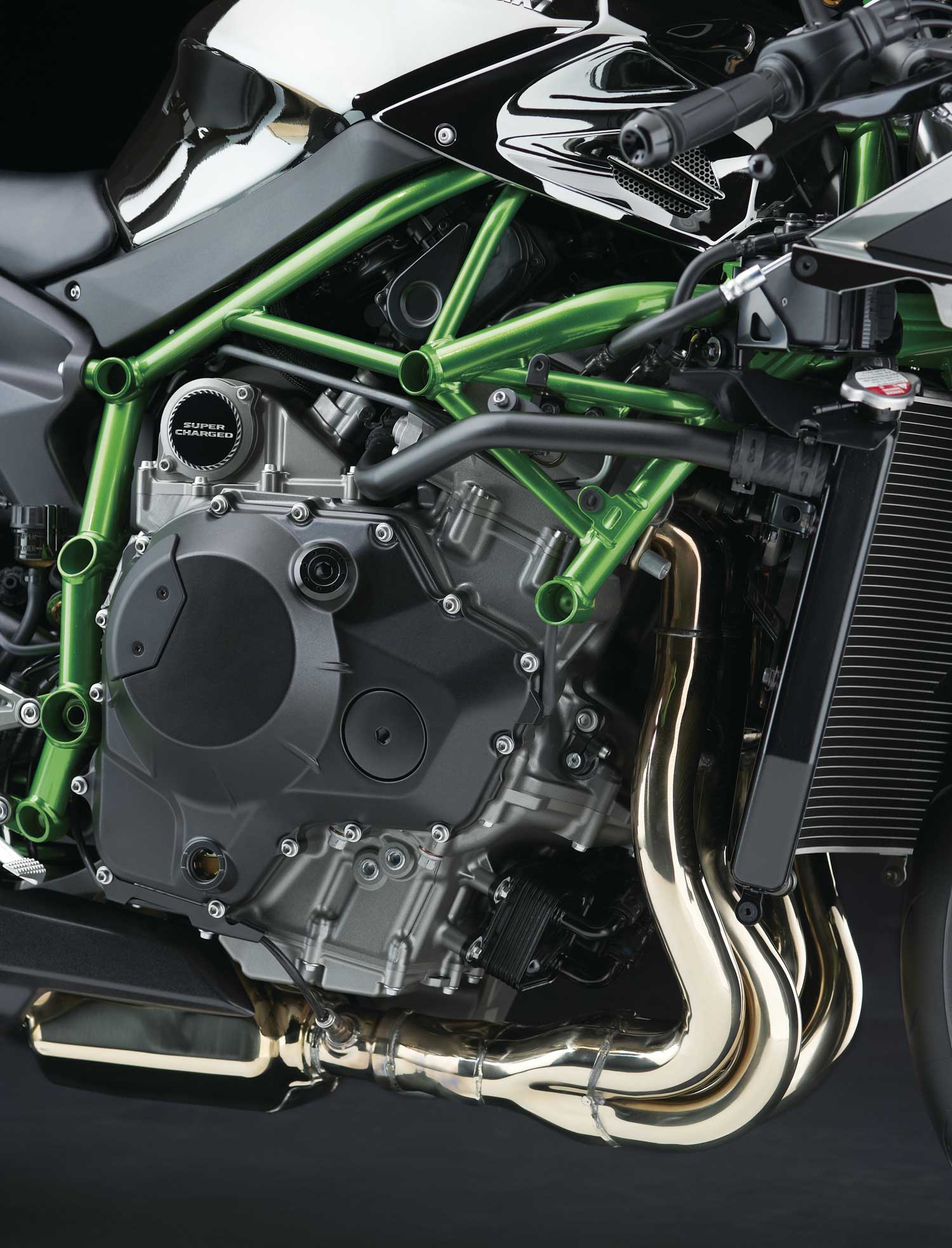

The H2’s peak power is some way off the 296bhp design goal that was quoted with the H2R, but the H2 – aside from the camshafts, head gaskets and clutch – has the same engine as the track bike, potentially making it powerful and reliable. The bike also uses a ‘dog-ring’ transmission, usually found in MotoGP and Formula 1 – a system that eliminates the need for selector forks, and thrives on fast gear changes. This is aided by a quickshifter, Brembo hydraulics and a slipper clutch to stop the back wheel from locking during downshifts.

The H2’s peak power is some way off the 296bhp design goal that was quoted with the H2R, but the H2 – aside from the camshafts, head gaskets and clutch – has the same engine as the track bike, potentially making it powerful and reliable. The bike also uses a ‘dog-ring’ transmission, usually found in MotoGP and Formula 1 – a system that eliminates the need for selector forks, and thrives on fast gear changes. This is aided by a quickshifter, Brembo hydraulics and a slipper clutch to stop the back wheel from locking during downshifts.

A Ram Air intake on the front is three times larger than the supercharger’s inlet, and pushes the motor’s output up to 210bhp; without it, the engine would produce 200bhp. With BMW’s S1000RR making 199bhp, the supercharger sounds less impressive, but the H2’s peak is reached at 11,000rpm, whereas the BMW hits it at 13,500rpm. The German bike also ‘only’ makes 83lb-ft of torque at 10,500rpm; the Japanese monster hits almost 99lb-ft at 10,500rpm.

We spoke to Richard Albans of TTS Performance – an expert in supercharger tuning: “A centrifugal supercharger, like that used by Kawasaki, tends to have a more progressive boosting characteristic, making such a powered motorbike very easy to ride – I’d say that the torque delivery is much more linear than a highly-tuned normally-aspirated engine that gives a rush of torque and power.” The H2 should get very fast, very quickly.

While the carbon-fibre fairing and wings have gone on the road bike, we still see the black-chromed plastic bodywork and the trellis frame on the single-seat only road bike. This steel-tube design is said to aid stability at high speed, whilst maintaining a more agile 1455mm wheelbase (a Hayabusa is 1480mm; the S1000RR is 1425mm). It also helps to dissipate engine heat, though the bike does weigh 238kg – less than the ‘Busa’s 260kg, but more than the BMW’s 204kg.

KYB AOS-II racing forks are fitted, with motocross-style air-oil separate cartridges, and a KYB fully-adjustable monoshock at the rear. Dual radial Brembo calipers bite 330mm semi-floating 5.5mm thick disks, and the rear wheel is knurled on the inside, to prevent the tyre from slipping.

As a statement of passion and ability, the H2R is a stunning machine. The H2 is the ‘sensible’ road-going sibling featuring traction control, launch control, engine braking control, electronic Öhlins steering damper, and ABS. Kawasaki has always said that the H2 would offer riders something they’ve never before experienced; it looks like the team has achieved it.

Watch all the Kawasaki videos on the exclusive YouTube channel

Here’s the official Kawasaki H2 press release in full:

The launching point for the development of the Ninja H2 project was a strong desire to offer riders something they had never before experienced. Convinced that a truly extraordinary riding experience would not be found on a motorcycle that merely built on the performance of existing models, the design team committed to developing the “ultimate” motorcycle from a clean slate. The bike needed to deliver intense acceleration and an ultra-high top speed, coupled with supersport-level circuit performance. To realise this goal, help was enlisted from other companies in the Kawasaki Heavy Industries (KHI) Group, precipitating an unprecedented level of inter-company collaboration.

Development pursued two paths. The first was a closed-course model (Ninja H2R) that allowed an unadulterated pursuit of performance free of the limitations that street riding would impose. This was followed by a street model (Ninja H2), based closely on the closed-course model, that would meet all market regulations. The results were incredible, with both models offering a sensory experience surpassing anything that riders can find today.

The Ninja H2 is powered by a supercharged engine based closely on that developed for the Ninja H2R. High output notwithstanding, the compact design is on par with power units found in supersport litre-class models. The key to achieving this incredible performance lies in the engine’s supercharger—a motorcycle-specific unit designed completely in-house with technology from the Gas Turbine & Machinery Company, Aerospace Company and Corporate Technology Division.

When it came time to name this model, using “Ninja”—a name synonymous with Kawasaki performance and shared by many legendary models over the years—was an obvious choice. But it is also named for another epoch-making model: the “H2” (also known as the 750SS Mach IV), powered by a 2-stroke 748 cm3 Triple, had an intense acceleration that made it a worldwide sensation. For a model that delivers supersport-level handling coupled with the kind of acceleration no rider has experienced before, we can think of no better name.

With the Ninja H2, Kawasaki is once again ready to unleash a new sensation upon the world.

The Kawasaki River Mark is a long-time symbol of the KHI Group dating back to the 1870s. As a policy, its use on products is rare and limited to models with historical significance. But for the Ninja H2 permission to use this symbol was granted.

The quest for power

In order to be able to offer intense acceleration, it was essential that the engine be able to produce big power. While a large-displacement engine could easily provide a high engine output, to ensure a lightweight, compact overall package a compact engine was also desired. Using a supercharged engine enabled both of these engine design requirements to be met: the Ninja H2 has a maximum output of 200 PS and its engine size is on par with other supersport litre-class power units. Aside from minor differences in the engine unit, and intake and exhaust systems tailored for street use to ensure it meets noise and emissions standards, the supercharged engine is essentially the same as the closed-course Ninja H2R, delivering an intense acceleration unlike anything you can experience on a naturally aspirated bike. Designed in-house, the immense potential of the highly compact, highly efficient engine is a testament to the technology possessed by the KHI Group.

Supercharged 998 cm3 in-line four

The supercharger used in the Ninja H2 was designed by Kawasaki motorcycle engine designers with assistance from other companies within the KHI Group, namely the Gas Turbine & Machinery Company, Aerospace Company, and Corporate Technology Division. Designing the supercharger in-house allowed it to be developed to perfectly match the engine characteristics of the Ninja H2. The highly efficient, motorcycle-specific supercharger was the key to achieving the maximum power and the intense acceleration that engineers wanted to offer.

* One of the greatest benefits of designing the supercharger in-house and tailoring its design to match the character of the Ninja H2 engine was that engineers were able to achieve high-efficiency operation over a wide range of conditions—something that would not have been possible by simply dropping in or trying to adapt an aftermarket automotive supercharger.

* The focus of the supercharged engine was not only on power, but also on acceleration and response. Driven by the engine rather than exhaust gas, a supercharger does not have the lag associated with a turbocharger. This means the benefit of stronger acceleration is available the instant the rider twists the throttle.

* The supercharger the engineers designed is a centrifugal-type unit—ideal for high-rpm performance—with a cast aluminium housing.

* The unit is located centrally, behind the cylinder bank, which is the best position to efficiently provide compressed air to all four cylinders evenly.

* The supercharger uses engine oil for lubrication. Not requiring an independent oil source contributed to a highly compact, lightweight design.

* Supercharger is driven by a planetary gear train, which runs off the crankshaft. Designing the gear train using technology from Kawasaki’s Aerospace Company resulted in a very compact unit, with minimal power loss.

* Gear train increases the impeller speed to 9.2x the crank speed (1.15x step gear x 8x planetary gear). This means that at maximum engine speed (approximately 14,000 min-1), the impeller shaft is spinning at almost 130,000 min-1.

* Impeller is formed from a forged aluminium block using a 5-axis CNC machining centre to ensure high precision and high durability. The 69 mm impeller features 6 blades at the tip, expanding to 12 blades at the base. Grooves etched into the blade surfaces help direct the airflow.

Power Unit designed to withstand the 300 PS output of the closed-course Ninja H2R

Despite it’s familiar In-Line Four configuration, the Ninja H2 power unit is loaded with technology developed specifically for this supercharged engine: some new, others with know-how from the Kawasaki Group. Every component of the engine was chosen to achieve a certain function. In order to accommodate the higher air pressure from the supercharger as well as ensure a high reliability with the over 300 PS output of the closed-course Ninja H2R, the whole engine was designed to be able to handle stresses 1.5x to 2x greater than on a naturally aspirated litre-class engine. In fact, aside from its camshafts, head gaskets and clutch, the engine unit is exactly the same as the unit designed for the Ninja H2R.

* Compared to a naturally aspirated litre-bike, the compression ratio is relatively low. But with the high-pressure air used in the supercharged engine, this compression ratio matched the high-output engine design.

– The combustion chamber is formed by machining; precise control of the chamber volume also helps prevent engine knock.

* A dummy head is used during the cylinder honing process. The more precise circularity and cylindricity that result allow the use of low-tension piston rings, which helps reduce mechanical loss.

* To ensure the engine receives sufficient fuel for its high output, the Ninja H2 uses a high-performance fuel pump.

Dog-ring Transmission

To facilitate smooth, quick shifting, a dog-ring type transmission was selected. This is the kind of transmission commonly found in MotoGP or Formula 1, and was developed with feedback from the Kawasaki Racing Team.

* Unlike a standard motorcycle transmission in which shift forks slide the gears into position, with a dog-ring transmission the gears all stay in place. Only the dog rings move, sliding into position to engage the desired gear.

Hydraulic Clutch & Back-torque Limiter

A high-quality hydraulic clutch offers less maintenance, ensuring the initial touch condition can be maintained. And with Brembo components, superb linearity and smooth actuation are also benefits.

* Brembo parts are used for both the clutch lever’s radial-pump master cylinder, and the clutch release mechanism. They receive extra attention from Brembo before being shipped to Kawasaki. Each part is examined and adjusted to eliminate any ineffective (idle) stroke, resulting in superb controllability.

* Back-torque limiter contributes to good stability by helping to prevent wheel hop when downshifting. The back-torque limiter is also adjustable.

Maximising airflow efficiency

All engines need to breathe. In addition to ensuring the engine has sufficient air, how the air is supplied is another concern. To maximise performance of the supercharged engine, airflow efficiency was of paramount importance. How air enters the supercharger, how the compressed air enters the engine, and then how the combusted fuel-air mixture is discharged were all carefully analysed for maximum efficiency and to ensure the airflow characteristics that would best match the desired engine character.

Ram air intake

* Air supplied to the supercharger enters via a single Ram Air intake in the left side of the upper cowl. The total frontal area is approximately 6,500 mm2, about 3x the area of the supercharger entrance.

* Ram Air duct was designed to take the fresh air to the supercharger in as straight a line as possible. Its shape was derived to match the impeller characteristics, further contributing to the engine’s high output.

Aluminium intake chamber

* Pressurised air exiting the supercharger is directed up into the intake chamber.

* Intake chamber has a large volume (6 litres), and is ideally shaped for high efficiency and high engine output.

* Being constructed of highly rigid aluminium offers two advantages: 1) aluminium offers excellent surface heat dissipation, helping to keep the intake air cool; 2) the rigid structure helps to ensure airtight performance with the supercharged air pressure (approximately 2 atm).

* A blow-off valve controlled by the ECU regulates pressure gain inside the intake chamber.

Electronic throttle valves

Kawasaki’s fully electronic throttle actuation system enables the ECU to control the volume of both the fuel (via fuel injectors) and the air (via throttle valves) delivered to the engine. Ideal fuel injection and throttle valve position results in smooth, natural engine response and the ideal engine output. The system also makes a significant contribution to reduced emissions.

* The simple system enables more precise control of KTRC, and facilitates implementation of other electronic systems like KLCM and KEBC (please see below).

Intake & exhaust ports, cam profiles

* Intake ports are polished to ensure smooth flow and minimise resistance.

* Straight exhaust ports—one for each exhaust valve—do not converge in the cylinder head. The straight-line design enables the most efficient egress of air from the combustion chamber, and also contributes to efficient chamber filling.

* Cam profiles were optimised for the 200 PS engine and are tuned to offer strong low-speed torque.

Exhaust system

* 4-2-1 style exhaust offers a compact layout with sufficient length for high performance.

* Entrance to the header pipes is ovular to match the dual exhaust ports per cylinder. Partly formed by hydroforming, each header pipe tapers from an ovular to a round cross-section. The collector pipes are also hydroformed.

* Designed to suit the output and characteristics of the 200 PS engine, the stainless steel header pipes have a diameter of φ45 mm. For the ideal exhaust pressure, all four header pipes are connected.

*. An exhaust device at the end of the chamber helps tune exhaust pressure waves.

* Right-side single silencer features a 10-sided cross section. Combined with the pre-chamber, it ensures that noise and exhaust gas emissions meet market regulations.

Keeping the engine cool

Cooling performance can be a substantial limiting factor for engine output, so maximising cooling efficiency was a key consideration when designing the engine. In addition to ensuring that intake air remain as cool as possible, the heat generated by the high-output engine needed to dissipated and engine components themselves needed to be kept cool to ensure efficient operation. The thorough pursuit of cooling performance led to a highly complex engine layout, both for the lubrication system (oil is used for cooling as well as lubrication) and the cooling system.

Cylinder head

A number of considerations were given to the cylinder head design to ensure the cooling performance needed for the supercharged engine. The large coolant passageways result in the ideal cooling for the combustion chamber.

* Water jacket extending between the twin exhaust ports of each cylinder, and large coolant passageways around the spark plug holes and the valve seat areas offer superior cooling. Spark plugs and valve seats, made of steel, have a greater tendency to retain heat than the aluminium cylinder head, so cooling them has a great effect.

* Large coolant exit (controlled by a thermostat valve) facilitates a greater volume of coolant flow through the cylinder head.

Oil jets

In the interest of keeping the engine compact and simple, a single lubrication system provides cooling oil for the engine components, supercharger and transmission.

* Oil jets lubricate the supercharger chain at the contact points (two places) where the chain meets the upper and lower gears.

* In addition to the two oil jets, the supercharger drive train’s lower gear has an oil passage.

* Inside the engine, there are two oil jets per cylinder to ensure the hot pistons are effectively cooled.

* Transmission oil jets (first use in a Kawasaki motorcycle) enable a compact transmission with high durability.

Lubrication system components

Because the lubrication system is servicing so many components, oil volume is 5.0 litres—about 35% greater than that usually seen in an engine of the same displacement.

* Large-sized oil pan with a deep sump holds sufficient oil to achieve thorough oil cooling for the system’s many lubrication points. The oil pan’s design ensures that the oil pump is always surrounded by oil (even during strong acceleration or deceleration) to prevent air ingestion.

Radiator

* Radiator’s size and capacity are on par with those found on current litre-class supersport models, but it offers superior cooling performance because it flows approximately 1.5x more air than other bikes.

* Airflow is facilitated by the compact side-cowl design, and except for the small under cowls, having the lower part of the engine open to the air was designed to pull hot air out.

Liquid-cooled oil cooler

* A liquid-cooled oil cooler adds to the extremely high cooling performance necessary for the high output engine.

High-speed stability and light handling

Designed for the performance parameters of the closed-course Ninja H2R and shared with the street-going Ninja H2, the objectives for the chassis were to ensure unflappable composure at ultra-high speeds, offer cornering performance to be able to enjoy riding on a circuit, and finally to have a highly accommodating character. Ordinarily, high-speed stability can easily be achieved with a long wheelbase, but a shorter wheelbase was selected to achieve the compact overall package and sharp handling that were also desired. The frame needed not only to be stiff, but also to be able to absorb external disturbances, which, when encountered while riding at high speeds, could easily unsettle the chassis. A new trellis frame provided both the strength to harness the incredible power of the supercharged engine, and the balanced flex to achieve the stability and pliability for high-speed riding.

Innovative chassis design

Using a trellis frame construction offered an elegant, lightweight solution to meeting the performance requirements for the chassis of the closed-course model. Able to harness the massive power of its more than 300 PS* engine, it has a balance of stiffness and flexibility that enables a very high level of stability while being able to handle external disturbances at high speeds. Its open design also helps effectively dissipate heat generated by the supercharged engine.

*Output on the Ninja H2R exceeds 300 PS; output for the Ninja H2 is 200 PS.

* Development of the trellis frame made good use of the latest analysis technology and substantial test rider feedback.

* Pipe diameter, thickness and bend of each piece of the trellis frame were carefully selected to obtain the necessary stiffness for that part of the frame. The trellis pieces are made primarily from high-tensile steel.

Swingarm mounting plate

This innovative new chassis mechanism allows the engine to act as part of the frame.

* Swingarm Mounting Plate bolts to the back of the engine. The swingarm pivot shaft goes through this plate, essentially allowing the swingarm to be mounted directly to the engine.

* Thanks to the Swingarm Mounting Plate, the frame does not need to use cross members for stability. This contributes to the frame’s light weight.

Single-sided swingarm

The Ninja H2 features Kawasaki’s first single-sided swingarm.

* Designed for high rigidity and light weight, the angular cross-section swingarm is composed of aluminium forged and pressed parts.

* Having a single-sided swingarm allows the exhaust silencer to be mounted closer to the bike centreline, ensuring a high bank angle for sporty cornering.

Chassis geometry

To ensure fun high-speed riding as well as circuit riding, a compact package was desired. Chassis geometry is very similar to that of a litre-class supersport model.

Front suspension

KYB AOS-II racing suspension makes its debut on a on-road bike.

* Based on the Air-Oil Separate cartridge fork developed for motocross racing, this is the industry’s first use of this high-performance racing suspension on an on-road motorcycle.

* Designed for low friction, the φ43 mm front fork offers superb action: smooth initial action is followed by strong damping at the end of the stroke.

* * Fully adjustable, the fork can be set to suit rider size, riding style and speed range. Adjusters for compression damping, rebound damping and preload are all located on the fork caps for easy adjustability.

Rear suspension

KYB fully adjustable mono-shock rear suspension offers superb stability.

* Top of the rear shock mounts to the Swingarm Mounting Plate. (Again, no need for frame cross-members.)

* The bottom of the rear shock is mounted via revised Uni-Trak linkage that offers excellent feedback regarding the rear tyre’s grip condition to the rider. The new linkage, situated below the swingarm also mounts to the Swingarm Mounting Plate.

*The rear shock is gas-charged with a piggy-back reservoir, ensuring stable damping performance. Rear shock can be adjusted for compression damping (high/low-speed), rebound damping and preload.

* The hydraulic preload adjuster, unitised with the shock body for a compact design, allows the preload to be adjusted by hand.

Brakes

Given the Ninja H2’s high-speed potential, the brakes chosen were the best available for a mass-production model. Special tuning then ensured that all play was removed from the system, so that when the brakes were called for they would respond immediately.

* A pair of massive φ330 mm Brembo semi-floating discs with a thickness of t5.5 mm deliver superb braking force.

* Grooves running down the centre of the outer edge of the discs increase their surface area for greater heat dissipation.

* Dual radial-mount Brembo cast aluminium monobloc calipers grip the front discs. The highly rigid opposed 4-piston calipers with φ30 mm pistons contribute to the Ninja H2’s superb braking force, as well as a high-quality image.

* Brembo radial-pump master cylinder and reservoir receive extra attention before being shipped to Kawasaki. Each part is examined and adjusted to eliminate any ineffective (idle) stroke.

* A large φ250 mm disc generates strong braking force at the rear.

* A Brembo opposed 2-piston caliper withφ32 mm pistons slows the rear disc and adds to the high-quality image.

* High-precision supersport-style ABS is standard equipment on the Ninja H2. Please see KIBS (Kawasaki Intelligent anti-lock Brake System) below.

Original-design wheels

Cast aluminium wheels were designed specifically for the Ninja H2.

* Star-pattern 5-spoke wheel design was selected based on analysis and testing to determine the optimum rigidity balance for high-speed performance.

* The analysis technology used in their development comes from World Superbike.

* Knurling on the inside of the rear wheel rim helps prevent the tyre from slipping on the wheel due to the massive torque generated by the engine.

High-speed tyres

To ensure sufficient tyre durability when riding at high speed, high-performance tyres must be used.

* A massive 200 mm rear tyre transmits the Ninja H2’s power to the tarmac. Tyres sizes are as follows:

Front: 120/70-17 Rear: 200/55-17

* The Ninja H2 is able to use high-performance street tyres. Its Bridgestone BATTLAX RACING STREET RS10 tyres are speed-rated for use up to 300 km/h.

Shaped for speed

As speed increases, wind resistance increases exponentially. To enable high-speed operation, a combination of high power and slippery aerodynamics was needed. With power requirements taken care of by the supercharged engine, the next step was to design bodywork that both minimised drag and added control when riding at high speed. Assistance from Kawasaki’s Aerospace Company was enlisted in creating the aerodynamically sculpted bodywork to ensure maximum aerodynamic efficiency.

Aerodynamics

It is no accident that when viewed from the side, the Ninja H2 does not seem to have the aggressive forward-canted stance of most modern supersport models. While supersport bikes use their front-leaning attitude to aid in quick steering, at the speeds for which the closed-course Ninja H2R was designed, such a posture would create drag that would hinder top speed aspirations. Instead, the stance is very neutral, almost flat—think Formula 1 car—to make the body as aerodynamically sleek as possible.

* Aerodynamically shaped upper cowl uses lips and lines to help direct airflow over its surface.

* Air passages on the left and right sides of cowl redirect air scooped up by the chin spoiler to the sides, helping to reduce drag.

* Upper cowl positions the Ram Air intake in the most efficient position.

* The upper cowl is formed from ABS*, with a shorter windscreen that balances wind protection and appearance.

* Compact side cowls and under cowls were designed to assist with heat dissipation.

* The rear cowl has an extremely compact three-piece design. The centre portion is taller, creating an aerodynamic form that helps smooth airflow as it passes the rider. Wind is also able to pass between the centre and side pieces, reducing air resistance.

Downforce generation

In order to maintain both straight-line stability and the control to change direction while running at high speed, the Ninja H2 features a number of aerodynamic devices to ensure the front wheel has strong contact with the ground.

* Design of the upper cowl incorporates a chin spoiler. This is not a cosmetic flourish; the downforce it creates contributes to high-speed stability.

* Contributing to high-speed stability, the Ninja H2 features mirror stays with airfoil cross-sections. Like the wings on the closed-course model, they were also designed by Kawasaki’s Aerospace Company. Their trailing edges are equipped with Gurney flaps that increase the effectiveness of the simple airfoil shape, allowing greater downforce to be generated with a smaller surface.

Man-machine interface

Although the Ninja H2’s high performance cannot be denied, since it was not intended to be a race bike designed to turn quick lap times as efficiently as possible, it did not need the spartan accommodation found on most purpose-built supersport models. The man-machine interface enables riders to enjoy the bike’s performance with a modicum of comfort. While the riding position, ergonomics and cockpit layout were all designed first and foremost to put the rider in the best position to control this amazing machine, the impression from the rider’s perspective is one not of austerity, but rather plush quality, high-tech control, and an impeccable fit and finish.

Riding position & ergonomics

The kind of riding for which the Ninja H2 was designed, and a desire for a compact overall package resulted in a riding position similar to that of a supersport without being quite as aggressive. As enjoyment of the intense acceleration and high-speed capabilities was the first priority, a solo seat for the rider is the only seating provided.

* The riding position was designed for riding at high speed and circuit riding. The rider triangle is similar to that of the Ninja ZX-10R, but more relaxed.

* To help support the rider during intense acceleration, hip-supporting pads flank the rear of the seat. The hip support is adjustable 15 mm backward to suit rider size.

* Machined footpegs feature a new design that includes ridges at the tip for extra grip.

Instrumentation & controls

The advanced, high-tech design of the instrumentation conveys the image of piloting a jet fighter aircraft. Handle control switches put all mode selection and display options at the rider’s fingertips.

* The new instrumentation design combines a full digital LCD screen with an analogue-style tachometer.

* LCD screen uses a black/white reverse display (white characters on a black background), contributing to the high-quality image. In addition to the digital speedometer and gear position indicator, display functions include: odometer, dual trip meters, current mileage, average mileage, fuel consumption, coolant temperature, boost indicator, boost (intake air chamber) temperature, stopwatch (lap timer), clock and the Economical Riding Indicator.

* Tachometer design uses an actual needle, but the black dial “face” looks blank until the engine speed increases. Backlit rpm numbers light up to chase the tachometer needle as it moves around the dial.

* Compact new handle switch design allows all instrument functions to be controlled from the handles.

Electronic rider support

Complementing the Ninja H2’s incredible engine and chassis performance, advanced electronics work behind the scenes to provide rider support. Depending on rider preference, many of the systems may be turned off. And while the high-performance engine was designed to be accommodating even without the benefit of electronic assistance, when electing to fully experience the Ninja H2’s intense acceleration or high-speed potential, these systems are available to provide an extra degree of rider reassurance.

Engine & Chassis Management Systems

KTRC (Kawasaki TRaction Control)

The new KTRC system used on the Ninja H2 combines the best elements of Kawasaki’s earlier traction control systems. Multi-level modes offer riders a greater number of settings to choose from, with each mode providing a different level of intrusion to suit riding conditions and rider preference, and all modes designed to manage output when a sudden slip occurs. The new system offers both enhanced sport riding performance and the peace of mind to negotiate slippery surfaces with confidence.

* Riders can choose from three modes, each offering a progressively greater level of intrusion. Each mode has three rider-selectable levels, adding more or less intrusion (rider preferences for each mode are programmable for on-the-move selection), for a total of nine possible settings. Riders may also elect to turn the system off.

* Mode 1 is for the circuit, Mode 2 for the street, and Mode 3 for wet pavement conditions. A Rain Mode is also available.

* Using complex analysis, the system is able to predict when traction conditions are about to become unfavourable. By acting before slippage exceeds the range for optimum traction, drops in power can be minimised, resulting in ultra-smooth operation.

* However, when excessive rear wheel spin is detected, engine output is reduced to a level that allows the rear wheel to regain grip. Fine control results in a very natural feeling: engagement is smooth, on/off transition is smooth, and stability is maintained during extended operation.

* Rain Mode can be turned on and off independently from KTRC. Activating Rain Mode sets KTRC to Mode 3+, and also limits power output, torque and response. Similar to a Low Power setting, maximum engine output is less than 50% of full, with a milder throttle response.

KLCM (Kawasaki Launch Control Mode)

Designed to assist the rider by optimising acceleration from a stop, KLCM electronically controls engine output to prevent wheelspin and minimise wheelies when launching.

* Riders can choose from three modes, each offering a progressively greater level of intrusion. Each mode allows the rider to launch from a stop with the throttle held wide open.

* KLCM can be used concurrently with KTRC.

KEBC (Kawasaki Engine Brake Control)

The KEBC system allows riders to select the amount of engine braking they prefer.

* When KEBC is activated (by selecting “LIGHT” in the KEBC settings), the engine braking effect is reduced, providing less interference when riding on the circuit.

KIBS (Kawasaki Intelligent anti-lock Brake System)

Kawasaki’s Supersport-style ABS is standard equipment on the Ninja H2. This is the same base system used on the Ninja ZX-10R, with programming and settings revised to suit the performance parameters of the Ninja H2.

* KIBS is a multi-sensing system, using the input from numerous sources. In addition to front and rear wheel speed sensors (standard for any ABS system), KIBS also monitors front caliper hydraulic pressure and various information from the engine ECU (throttle position, engine speed, clutch actuation and gear position).

* High-precision brake pressure control enables the system to avoid reduced brake performance due to excessive pressure drops, allows lever feel to be maintained when KIBS is active, and ensures ABS pulses feel smooth (not heavy).

* High-precision brake pressure control also offers a number of sport riding benefits:

1. Rear lift suppression

2. Minimal kick-back during operation

3. Accounting for back-torque

* On the Ninja H2, KIBS is always active.

KQS (Kawasaki Quick Shifter)

The Ninja H2 is the first Kawasaki motorcycle to be fit standard with a quick shifter.

* Complementing the engine’s strong power and the dog-ring transmission, a contactless-type quick shifter enables quick upshifts for seamless acceleration.

Öhlins Electronic Steering Damper

Unlike a mechanical steering damper—in which the settings, once fixed, must cover all riding conditions and speeds—the damping characteristics are changed electronically according to vehicle speed, and the degree of acceleration or deceleration. At low speeds, the settings were chosen such that damping does not interfere with the bike’s intrinsic lightweight handling. At high speeds, damping increases to provide enhanced stability.

* Kawasaki’s electronic steering damper was jointly developed with Öhlins, one of the most popular and respected manufacturers of steering dampers.

* Electronic steering damper provides just the right amount of damping based on what the bike is doing. Using input from the rear wheel speed sensor (provided via the engine ECU), the electronic steering damper’s ECU determines the vehicle’s speed as well as the degree the bike is accelerating or decelerating.

Styling and craftsmanship

Wanting to ensure a bold design worthy of a model that carried both the “Ninja” and “H2” names, the prime styling concept chosen for the Ninja H2 was “Intense Force Design.” As a flagship for the Kawasaki brand, it required presence, and a styling that reflected its incredible performance. But the design is much more than cosmetic. While its edged styling certainly looks the part, the Ninja H2 also possesses a functional beauty: each piece of its bodywork was aerodynamically sculpted to enhance stability at high speeds; the cowling design also maximises cooling performance and heat dissipation, aiding in achieving the engine’s incredible output; and the Ram Air duct is ideally positioned to bring fresh air to the supercharger. More than any motorcycle Kawasaki has built to date, the Ninja H2 is a showcase of craftsmanship, build quality and superb fit and finish—right down to the high-tech mirrored-finish black chrome paint specially developed for this model.

Styling & Craftsmanship Details

* Machined surfaces on the wheel spokes and painted rims contribute to a high-quality finish.

* High-level attention to detail is evident in the numerous machined bolt and nut designs (e.g. the steering stem and rear hub nuts).

* Welding bead quality for the trellis frame is uniformly very high, contributing to the Ninja H2’s superb fit and finish. Depending on the weld, some are efficiently and precisely welded by Kawasaki robots, while others are welded by expert Kawasaki craftsmen.

Lighting Equipment

The Ninja H2 is equipped with all the lights needed for street-legal operation. With the exception of the bulb illuminating the license plate, all lighting equipment on the Ninja H2 is of the LED type.

* Bright, compact LED headlamp positioned low, at the front of the upper cowl, contributes to the “Intense Force” design.

* * Design of the LED front position lamps brings to mind the sharp fangs of a predator.

* Front LED turn signals are built into the mirror housings.

* Elegant LED taillight is flanked by surface-emitting LED position lamps.

* New-design LED rear turn signals featuring an inner lens, surface texturing and surface-emitting LEDs contribute to the bike’s high-quality image.

High-tech Paint

The mirrored-finish black chrome paint used on the Ninja H2 was developed by Kawasaki specifically for motorcycles. The highly reflective surface adds to the bike’s stunning design.

* In the shade the paint appears black, but once in the sunlight its highly reflective surface takes on the appearance of the surrounding scenery.

* While this kind of paint may be found in custom circles, this is its first use on a mass-production vehicle in either the automotive or motorcycle industries.

* The highly reflective surface is created by inducing a silver mirror reaction (a chemical reaction between a solution of silver ions and a reducing agent) that forms a layer of pure silver. Each layer of the paint is carefully finished by the hands of Kawasaki craftsmen to ensure a brilliant, lustrous surface.

Kawasaki River Mark

Special permission was obtained to use the River Mark on the Ninja H2. Usually, its use on a product is reserved for models of historical significance.

* The River Mark emblem proudly displayed on the upper cowl. This is the first use of a 3D standalone version of the River Mark emblem.

* The River Mark is also displayed on the upper triple clamp and on the ignition key.

High-precision Production

Unlike a standard mass-production model, the high-precision production of the Ninja H2 requires greater hands-on participation by skilled Kawasaki craftsmen. Each step, from metalworking, treatment, welding, painting to assembly, fine-tuning and inspection is carefully attended to in order to create a product of superior quality. Within Kawasaki’s Akashi Factory, production takes place in an area dedicated exclusively to the Ninja H2.

Tech Spec

ENGINE

Type: Liquid-cooled, 4-stroke In-Line Four

Displacement: 998 cm3

Bore and Stroke: 76.0 x 55.0 mm

Compression ratio: 8.5:1

Valve system: DOHC, 16 valves

Fuel system: Fuel injection: φ50 mm x 4 with dual injection

Intake system: Kawasaki Supercharger

Ignition: Digital

Starting: Electric

Lubrication: Forced lubrication, wet sump with oil cooler

DRIVETRAIN

Transmission: 6-speed, return, dog-ring

Final drive: Chain

Primary reduction ratio: 1.551 (76/49)

Gear ratios:

1st: 3.188 (51/16)

2nd: 2.526 (48/19)

3rd: 2.045 (45/22)

4th: 1.727 (38/22)

5th: 1.524 (32/21)

6th: 1.348 (31/23)

Final reduction ratio: 2.444 (44/18)

Clutch: Wet multi-disc, manual

FRAME

Type: Trellis, high-tensile steel, with Swingarm Mounting Plate

Wheel travel: front: 120 mm; Rear: 135 mm

Tyre: front: 120/70ZR17M/C (58W) ; Rear: 200/55ZR17M/C (78W)

Caster (rake): 24.7o

Trail: 108 mm

Steering angle (left/right): 27o / 27o

SUSPENSION

Front: φ43 mm inverted fork with rebound and compression damping, spring preload adjustability and top-out springs

Rear: New Uni-Trak with gas-charged shock, piggyback reservoir,

dual-range (high/low-speed) compression damping, rebound damping and preload adjustability, and top-out spring

BRAKES

Front: Dual semi-floating φ330 mm discs; Dual radial-mount, opposed 4-piston

Rear: Single φ250 mm disc ; Opposed 2-piston

DIMENSIONS

Overall length: 2,085 mm

Overall width: 770 m

Overall height: 1,125 mm

Wheelbase: 1,455 mm

Ground clearance: 130 m

Seat height: 825 m

Curb mass: 238 kg

Fuel capacity: 17 litres

PERFORMANCE

Maximum power: 147.2 kW {200 PS} / 11,000 min-1

Maximum power with Ram Air: 154.5 kW {210 PS} / 11,000 min-1

Maximum torque: 133.5 Nm {13.6 kg¦m} / 10,500 min-1

The specifications mentioned here apply to and have been achieved by production models under standard operating conditions. We intend only to give a fair description of the vehicle and its performance capabilities but these specifications may not apply to every machine supplied for sale. Kawasaki Heavy Industries, Ltd. reserves the right to alter specifications without prior notice. Equipment illustrated and specifications may vary to meet individual markets. Available colours may vary by market.